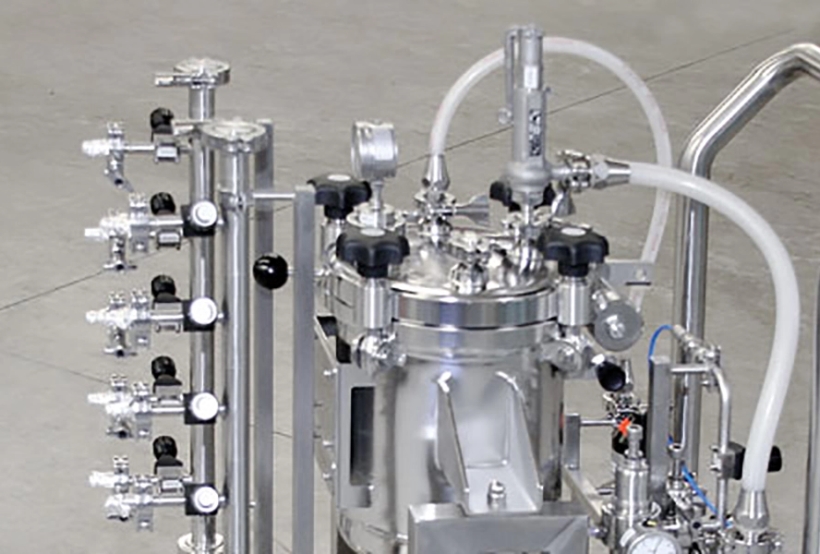

The vacuum separator consists of two main components, the collecting vessel B1 and the drainage vessel B2. A vacuum is created in the two vessels and the vessels filled with process water via tube and hose lines. When the limit level is obtained, the connecting valve between the two vessels closes and pressure builds in drainage vessel B2 to drain the content over strainer into the sewer. The contact lenses or lens remains collect in two switchable strainer vessels. The strainers must be emptied manually and are not included in the disinfection process, i.e., the strainer and the filter baskets must be cleaned manually.